Introduction:

The lack of incubator for hatching the eggs of improved breed has been really a major problem being faced by the poultry farmers of Barpeta district. Majority of the poultry farmers are economically backward and hence procuring an artificial incubator is hardly feasible for them. Md. Faruk Khan is an educated rural youth of Barpeta. Being a youth from the community who is mainly involved in poultry rearing Md. Khan was very much concerned about this problem and tried to do something for the farmers to ease the problem. After dedicating so much of his valuable time pondering on the specific problem of hatching he came out with a solution that has revolutionized the whole hatching scenario of the district.

Apart from the above, Md. Khan from his childhood, also saw that during the peak period of harvesting huge quantity of vegetables got spoiled in the different markets of Barpeta due to fall in price. When he achieved his 25 years of age, he thought that he would start a food processing industry to take advantage of the situation. Accordingly, he took nos. of training on food processing specially preparation of pickles, squash, jam & jelly from various institutions including KVK, Barpeta. Then, he started his food processing industry in his home in a small scale about 10 years back and gradually tried to expand his industry. Now, Md. Faruk is a renown agri- entrepreneur in food processing sector in Barpeta district. Presently, he is also invited by various organizations as resource person to train the SHGs for training on value addition of food products.

About the Innovation:

Title: Home made low cost incubator for hatching egg

Problem /challenge addressed :

High cost involved in hatching eggs by incubator and less no of eggs (15-20) can be hatched by mother bird.

Description of innovative practice/ technology:

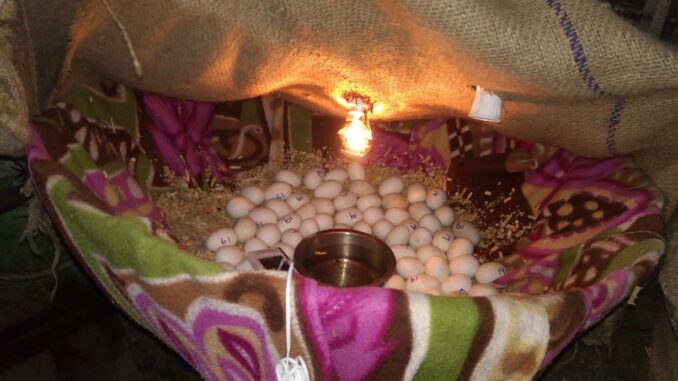

The incubator is made from 2 numbers of bamboo baskets with 3 ft diameter. One basket is used as lid over the other. The basket used as lid has one hole in the middle in which a 60 W bulb with regulator is fixed. The bulb is coloured with black paint. Saw dust is used in the basket for keeping the eggs. Both the baskets are covered with blanket for maintaining the temperature. 2 L of water is kept in a steel container in the middle of the lower basket for maintaining humidity. The eggs are rotated four times daily for maintaining uniform temperature and humidity throughout. The eggs are hatched after 28 days.

Practical Utility of Innovation:

- Farmers can afford the low cost incubator

- More numbers (10 times) of eggs can be hatched as compared to natural hatching

- Natural incubation does not happen in case of improved breed.

Economics of innovation:

| Particulars | Fixed cost |

| Bamboo basket 2 nos | Rs. 300.00 |

| Bulb 60 W | Rs. 15.00 |

| Blanket 2 nos | Rs 300.00 |

| Steel pan | Rs 150.00 |

| Digital thermometer | Rs 300.00 |

| Total cost | Rs. 1065.00 |

| Operational Cost | |

| Eggs for 150 eggs @ Rs 8/- per egg | Rs 1200.00 |

| Electricity cost | Rs. 200.00 |

| Total Cost | Rs. 1400.00 |

| Gross income by selling 120 duckling (80% of total numbers of eggs) @ Rs 50/- per duckling | Rs. 6000.00 |

| B.C. ratio (Gross income/operational cost) | 4.29 |

Income from Food Processing Industry:

Gross income: Rs. 10 lakh/Year

Net income: Rs. 3 lakh/year (30% of gross income)

Impact:

- Farmers of different villages of the district adopted the technology and they are getting very good result.

Horizontal Spread:

- About 150 farmers have adopted the technology.

Award Received:

- Md. Faruk Khan received Innovators Award from ICAR in the Farmers Innovators’ Meet held at Gangtak, Skkim during April 20-21, 2018.